Choose a Toster Oven for Reflow Soldering

Since you will be cooking some nasty things inside your oven you are going to need a dedicated oven for your reflow soldering. DO NOT COOK FOOD IN YOUR REFLOW OVEN!

If you have an unused oven lying around you can try to use it before going out and buy a new one, but if you need to get a new oven there are some things to keep in mind when choosing it to buy the best you can for your job.

Controls

Avoid the new electronics controlled oven with cool displays and touch buttons.

You are not going to use those controls and you can save some money by getting a basic one with only manual controls.

If do not plan to open and modify internally the oven make sure that you can turn it always on with the supplied knobs. If you want to reflow with lead-free solder paste there is the possibility that the thermostat of the oven will shut it down before the temperature you need to reach. If this happens, you will have no other choice than open the oven and bypass the thermostat control knob.

Dimensions and Power Rating

As a general rule, keep in mind that, since larger ovens have more mass, they tend to heat and cool down slower than the smaller ones. In other words they have much more “thermal inertia” which is ok for cooking but definitely you want to minimize it for reflow soldering.

Because of that, you may want to start searching for the smaller oven with the highest power rating you can find in the market. Something around 1500W for a small oven is almost perfect.

If you really need to use a larger oven you should consider modding it to add some more heating elements but before doing any modification check for your power outlets power rating.

If you live in a country where the outlets have a standard rating of 110V/120V@15A you can’t draw more than 1500W and you cannot modify your oven unless you ask your energy supplier to install a 220V/230V power line.

Convection Fan

A circulating air fan is not needed but it may help to improve heat consistency across your PCB.

Industrial reflow ovens basically work by convection. They are designed to minimize radiated energy from the heaters and to use only hot air to transfer heat to the PCB with one or more fans which not only keeps the temperature gradient in the oven to a minimum but also draw the hot air out when there are overshoots and during cooldown phase.

A toaster oven on the other hand works basically with radiated energy from the heaters and the small fans they usually come from are often not adequate to ensure a minimum heat gradient. In our tests, we found that sometimes they can help but, depending on the oven and the fan itself, they may cause problem during the liquidus phase. Sometimes they have strong vibrations and sometimes they spin too fast with too much airflow on small areas. Both of these problems usually results in the smaller components being moved out of their places.

The only way to know if your oven’s fan is ok is to actually try it.

For small PCB with small components you should be ok with the fan OFF. If you have bigger components you can try to turn on the fan during the entire reflow process.

If your board has a mix of bigger and smaller components you can try to turn on the fan only during PREHEAT and SOAK.

Also keep in mind that turning on the fan usually results in an increase of thermal inertia and tuning your profile may become somewhat harder and, if you plan to use an oven without having to open and modify it internally, there is no way to externally control the fan which is usually always on.

Heaters

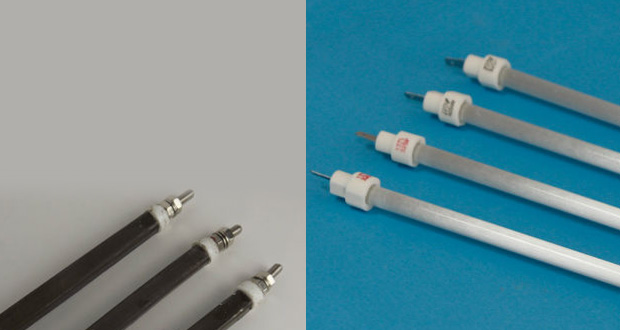

There are two kind of heaters usually mounted inside a toaster oven: the classic ceramic heaters (the ones you find inside your big kitchen oven) and the newer quartz heaters.

While both of them can do the job of rising temperature high enough for reflowing, quartz elements tends to heat up and cool down faster.

This will improve the response of the oven to your reflow profile so, if you can, get an oven with quartz elements.

The position of the heaters in the oven is also important. If you have only one heater on the top and one at the bottom you will probably have a few problem with larger boards with some hot spot directly under the heating elements and a few cold spot in the farther locations.

Ideally there should be at least two elements on the top and two at the bottom.

If you have to decide, it is better to have two heaters on the top and none at the bottom. This will drastically improve heat distribution but could also lead to warped boards for larger PCB (more than 10cmx10cm). Try to choose an oven which is adequate to the boards you are going to reflow.